Understanding the MCC Panel: Definition and Core Function

What Is an MCC Panel?

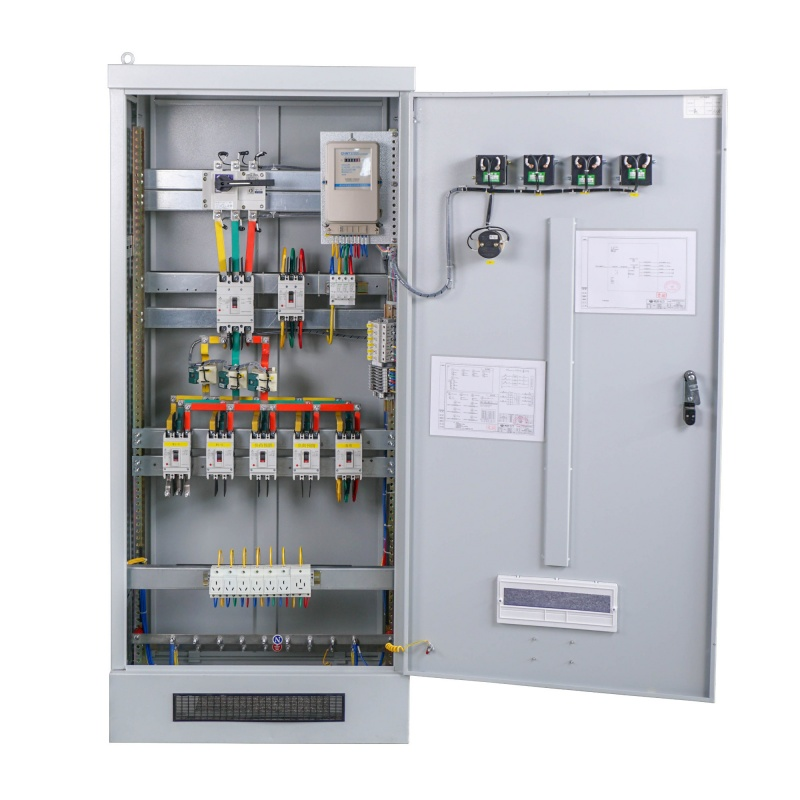

MCC panels, also known as Motor Control Centers, serve as central hubs for managing all those electric motors running throughout industrial sites. These systems bring together things like motor starters, protective circuits, and various monitoring tools inside one big metal box. From this single point, plant workers can control pretty much everything from pumps and conveyor belts down to air compressors without having to run around the facility. The whole setup makes it much easier when something goes wrong because technicians don't have to hunt through miles of wiring to find issues, especially important places where lots of electrical power is constantly being used such as car manufacturing plants or wastewater processing stations.

How Does an MCC Panel Work in Industrial Power Systems?

MCC panels use layered bus bar systems to distribute electricity safely:

- Horizontal bus bars channel incoming power (typically 600V–3200A) across the panel.

- Vertical bus bars branch power to individual motor starters (100A–1200A).

- Unit stab connections link each motor to its dedicated control unit.

Automated transfer switches maintain continuity by switching to backup power during outages, while built-in circuit breakers and overload relays protect against electrical faults.

Key Components of an MCC Panel and Their Roles

| Component | Function |

|---|---|

| Motor Starters | Safely energize motors via contactors and relays |

| Bus Bars | Distribute power with minimal resistance |

| Protection Devices | Circuit breakers, fuses, and thermal relays guard against overloads |

| Control Interfaces | Enable local or remote operation through push buttons or SCADA systems |

This modular design allows factories to scale operations while maintaining precise control over motor-driven processes.

Centralized Control and Operational Efficiency

Streamlining Motor Management with Centralized MCC Systems

Factories today rely on MCC panels to bring all those motor controls together under one roof instead of having control boxes everywhere. Some recent research from 2024 suggests that when plants switch to this system, they cut down on hands-on work by around 37%, though actual savings might vary depending on the setup. What makes these panels so useful? Well, operators can keep an eye on things like motor temps and vibrations right from their main dashboard. When something goes wrong, they don't have to run around looking for individual switches because everything's connected through those built-in overload relays and starters. It just makes sense for anyone trying to streamline operations while keeping equipment running smoothly.

Reducing Downtime and Increasing Production Uptime

MCC panels employ predictive algorithms that analyze historical motor data to forecast maintenance needs. During voltage fluctuations, automated circuit breakers disconnect faulty motors within 200 milliseconds–68% faster than manual shutdowns in legacy systems. This swift protection helps maintain production continuity for critical equipment like conveyor systems and pumps.

Case Study: Efficiency Gains in Automotive Manufacturing

A tier-1 auto parts manufacturer reduced unplanned downtime by 41% after deploying smart MCC panels across 127 production motors. Centralized programming enabled quick reconfiguration of stamping press schedules during model changeovers. Energy monitoring identified underutilized HVAC motors, resulting in 19% annual power savings–consistent with findings from the 2024 Industrial Automation Report.

Safety, Protection, and Risk Mitigation

MCC panels enhance worker safety and ensure operational continuity through layered protective systems. These industrial control hubs minimize electrical hazards while supporting uninterrupted production–a crucial balance in high-risk manufacturing environments.

Integrated Protective Devices in MCC Panels for Electrical Safety

Inside motor control center panels, circuit breakers team up with overload relays and ground fault detectors to catch problems before they turn serious. According to NFPA 2024 standards, thermal sensors actually spot rising motor temps about 12 percent quicker compared to regular standalone units. This early warning system cuts down on potential fires and saves expensive equipment from getting damaged. For newer installations, manufacturers are now using Class 10 or 20 electronic overload relays which react lightning fast when there's a sudden surge in current flow. These advanced models can detect and respond to power spikes within just 30 milliseconds flat, making them far superior to older mechanical systems for protecting industrial motors.

Arc Flash Reduction and Operator Safety Features

MCC panels designed to resist arcs typically incorporate current limiting fuses along with heavy duty steel frames that help keep dangerous energy contained during faults. According to research published by IEEE last year, manufacturing facilities that switched to these specialized panels saw around three quarters reduction in arc flash events compared to older systems. The front access design is another big plus for safety teams. These panels come equipped with insulated bus bars so technicians can perform maintenance tasks without having to reach behind where live parts might be present. This setup naturally meets OSHA requirements outlined in section 1910.303 while making day to day operations much safer for everyone involved.

Balancing Automation and Human Oversight in Fault Response

When there's a ground fault detected, most automated MCC panels will shut down motors within just 50 milliseconds. At the same time, those programmable logic controllers, or PLCs as we call them on site, send alerts right to the technician's HMI interface so they know what's happening. Safety first folks always mention manual overrides as critical backup measures. According to NECA's 2023 report, these manual controls show up in almost nine out of ten industrial accident investigations. That makes sense when you think about it. Most factories have strict rules requiring two separate confirmations before anyone can restart equipment after a high voltage trip. This extra step keeps human oversight part of the equation alongside all our fancy automation systems.

Scalability and Modular Design for Future-Ready Factories

Modular Architecture of MCC Panels and System Flexibility

Today's modern MCC panels come with modular setups that allow factory operators to expand their operations without tearing apart existing infrastructure. These aren't your standard fixed systems anymore. The design makes it simple to add new parts or swap out old ones when needed, whether it's circuit breakers, those VFD motors we all know and love, or just plain motor starters. What does this mean practically? Well, companies can save anywhere from 20 to 35 percent on upfront costs compared to what they would spend on traditional systems. Plus, these panels meet the IEC 61439 requirements for industrial electrical equipment, which is becoming increasingly important as safety regulations tighten across manufacturing sectors.

Planning for Expansion: Adaptable MCC Configurations

Smart manufacturers today are opting for MCC panels that feature separated busbars along with consistent module dimensions. The real advantage comes when they need to expand capacity later on something like squeezing in an extra 10 or so percent worth of motor controls without needing more room on the factory floor simply by slotting in pre-made components during routine maintenance checks. According to recent findings from the Industrial Automation Report released last year, facilities in the food processing sector saw their retrofitting time drop by around 40% thanks to these modular systems because there was no need to completely rewire entire electrical setups across the plant.

Case Study: Retrofitting a Textile Plant with Expandable MCC Units

A mid-sized textile manufacturer upgraded its legacy MCC infrastructure with modular units, achieving 30% faster production line reconfigurations. The project included:

- Phase 1: Replacing fixed feeder sections with plug-in busways (6-month ROI)

- Phase 2: Adding IoT-enabled motor starters to 18 spinning machines

-

Phase 3: Integrating 25% more capacity during a weekend shutdown

The upgrade reduced annual energy waste by 12% and allowed seamless integration of solar-powered looms two years later.

Energy Efficiency and Smart Automation Integration

Optimizing Energy Use with VFDs in MCC Panels

VFDs installed in MCC panels can change how fast motors run depending on what's needed at any given moment. These drives save quite a bit of power too - around 18 to 25 percent according to some recent studies from the World Business Council for Sustainable Development back in 2024. When industries switch away from those old fixed speed setups, they keep their processes running smoothly without wasting so much energy. Most big equipment makers are starting to build these variable frequency drives right into their MCC panel designs nowadays. This makes it easier to manage whole systems of pumps and conveyor belts from one central location instead of having separate controls everywhere.

Integrating PLC, SCADA, and IIoT for Real-Time Monitoring

Today's Motor Control Center systems bring together PLCs for automated control along with SCADA interfaces and those IIoT sensors we keep hearing about. When these components work together, factory supervisors can monitor how much electricity is being used through live dashboards on their screens. Plus they can tweak machine operations when demand drops off during slower hours. What makes this setup so effective? Well, the whole system basically stops machines that aren't needed from guzzling power unnecessarily. According to recent studies, this approach tackles around two thirds of all avoidable energy losses happening in production facilities across the country.

AI and Predictive Maintenance in Modern MCC Systems

Artificial Intelligence (AI) analyzes historical performance data from MCC panels to predict insulation degradation or contact wear 6–8 weeks before failure. This proactive approach reduces unplanned downtime by 41% and improves maintenance efficiency. Advanced systems can reroute power during thermal anomalies, sustaining operations while scheduling repairs during planned outages.

FAQ Section

What are MCC panels used for? MCC panels are central systems utilized in industrial settings to control and monitor electric motors and other electrical components throughout facilities.

How do MCC panels improve operational efficiency? MCC panels streamline motor management by centralizing control, reducing manual labor, and using predictive algorithms for maintenance, thus optimizing production uptime.

What safety features do MCC panels offer? MCC panels include protective devices like circuit breakers and overload relays to minimize electrical hazards, reduce arc flash incidents, and ensure operator safety through automation and manual overrides.

How do MCC panels support scalability? MCC panels have modular designs allowing easy upgrades and expansion, saving costs, and facilitating flexible retrofitting without extensive changes to existing infrastructure.

What role does AI play in MCC panels? AI in MCC panels predicts maintenance needs based on historical data, enhancing efficiency by avoiding unplanned downtimes and optimizing repairs.