Understanding Substation Automation in Modern Power Networks

Defining Substation Automation Systems

Substation automation basically means using digital tech to run substation operations automatically, making power distribution work better and stay reliable longer. The heart of most systems these days is something called SCADA, short for Supervisory Control and Data Acquisition. This lets engineers watch and control big electrical grids from afar. With SCADA in place, workers get all sorts of live data coming in constantly. They can spot problems before they become major issues and adjust things on the fly when needed. Power companies that implement good substation automation typically see fewer blackouts and waste less energy overall. The savings add up fast across large utility networks.

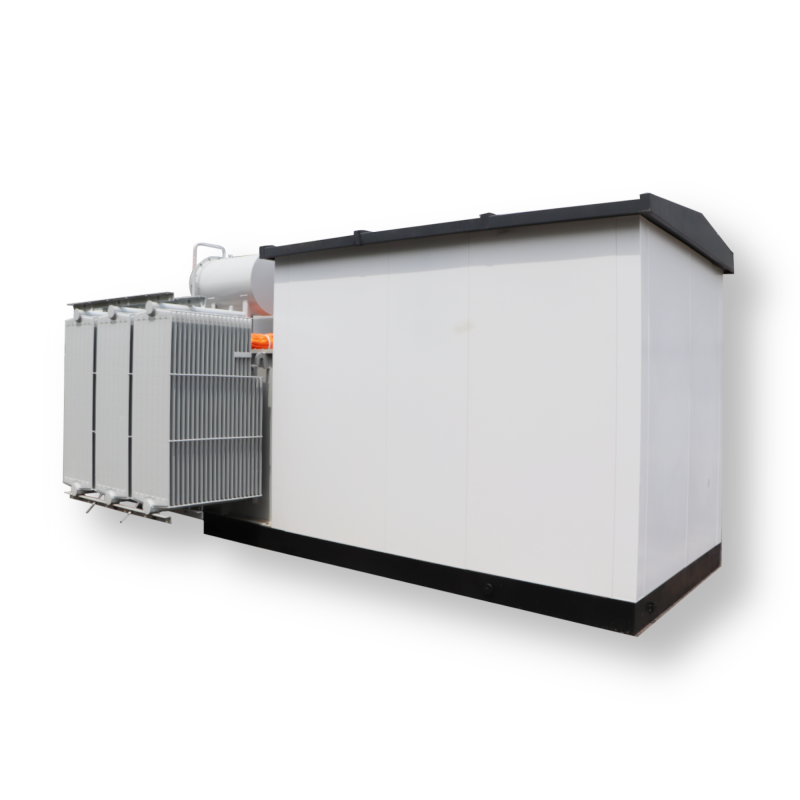

Key Components: From Electrical Distribution Panels to Smart Control Cabinets

Substation automation relies heavily on electrical distribution panels and smart control cabinets that manage power flow and contain those important IEDs we all talk about. Distribution panels basically act as traffic directors for electricity running through different circuits, making sure everything flows where it needs to go without wasting energy. Smart control cabinets take things further by adding features like real-time monitoring, remote control capabilities, and early warning systems when something goes wrong in the grid. When these pieces work together properly, service reliability improves significantly and maintenance becomes much more proactive than reactive. Utilities using this kind of smart infrastructure actually spot potential problems long before customers even notice an outage, keeping the lights on across entire regions while cutting down on unexpected failures throughout the whole electrical system.

Core Technologies Driving Grid Transformation

Intelligent Electronic Devices (IEDs) and Their Functions

Intelligent Electronic Devices or IEDs play a central role in today's substation automation systems and are pushing electrical grids toward smarter operation. These gadgets collect and process data in real time, making it possible to monitor and control electrical systems effectively across power networks. When something goes wrong, IEDs spot problems fast and respond accordingly, helping protect expensive equipment from potential damage during faults. For utility companies looking to upgrade their infrastructure, spending on better IED tech means stronger system reliability, fewer service interruptions, and staying ahead of competitors in an industry that keeps changing rapidly as demand grows and regulations tighten.

Communication Protocols in Medium Voltage Control Cabinets

Good communication inside medium voltage control cabinets makes all the difference when it comes to running substations smoothly. Standards such as IEC 61850 play a big role here by letting different equipment talk to each other properly. This means data gets shared consistently across systems and problems get addressed faster when something goes wrong. For utility companies wanting to automate their substations successfully, these kinds of standards matter a lot because they actually allow diverse pieces of hardware to work together without constant headaches. The protocols help with monitoring everything in real time while controlling operations on site. Plus, they make it possible to spot potential issues before they become serious through predictive maintenance techniques. All this adds up to better performance and fewer outages throughout the entire power grid.

Data Acquisition in Power Distribution Control Cabinets

Collecting data from power distribution control cabinets is really important for managing today's electrical grids effectively. These systems gather key operational information which helps engineers analyze performance, generate reports, and find problems before they become major issues. When utilities have good data acquisition set up properly, they can plan better for the future of their grid operations. The ability to monitor these systems improves overall stability across the network while allowing maintenance teams to address potential failures before they happen. This leads to a more intelligent electrical distribution system that delivers consistent service to customers without unnecessary downtime or wasted resources.

Operational Benefits for Utility Providers

Enhanced Reliability Through Low Voltage Control Systems

Low voltage control systems really improve how reliable electrical networks are because they bring in those dependable automation features we all need these days. What makes them stand out is their ability to find problems fast and get things back online quicker than traditional methods. Think about it this way: when there's a fault somewhere in the grid, these systems jump into action almost immediately, cutting off just the affected area so everything else keeps running smoothly. Utility companies looking to upgrade their infrastructure should seriously consider low voltage controls since they cut down downtime and save money in maintenance costs. Customers notice when power stays on without unexpected blackouts, which builds trust over time. People want to support companies they can rely on, especially during those hot summer days when air conditioning matters most.

Real-Time Monitoring in Electrical Distribution Panels

Adding real time monitoring to electrical distribution panels gives power companies much better control over sudden problems and helps them distribute electricity more efficiently. The sensors and meters installed in these panels track everything from voltage levels to load fluctuations across different parts of the network. When something goes wrong, operators get instant alerts so they can fix issues fast. This constant stream of data makes the whole system more stable and stops major outages that could leave thousands without power. Utilities spend a lot of time watching their systems through these monitoring tools, catching small problems early before they turn into bigger headaches for customers and repair crews alike.

Cybersecurity Considerations for Smart Control Cabinets

More automation means we need stronger cybersecurity protections for those smart control cabinets if we want to keep them safe from bad actors. Good cybersecurity practices help protect all that valuable information while stopping people who shouldn't be getting into our control systems. The expansion of automation across utility networks actually makes things riskier from a cyber perspective. That's why utility companies must focus on training their staff about online security risks and invest in better security software solutions. Keeping these automated systems secure isn't just something nice to have anymore. It's essential for building customer confidence and ensuring reliable service delivery in today's connected world. When utilities fail here, everyone pays the price through service disruptions and lost trust.

Implementation Challenges and Solutions

Retrofitting Legacy Systems with Modern Automation

Upgrading old systems with new automation tech is no small feat because of all those compatibility problems and the mountain of work needed for full upgrades. Most legacy systems run on infrastructure that's way behind the curve when it comes to working with today's automation solutions, which makes getting everything updated quite complicated. But there's hope if utility companies plan carefully and get good advice from people who know what they're doing. The key lies in following proven methods and taking things step by step. Many successful modernizations start with small changes first. Take incremental approaches where possible, implement improvements in stages rather than trying to overhaul everything at once. This gradual shift helps avoid major service interruptions while still improving how well the whole system operates over time. Some companies find that starting with one section of their network gives them valuable experience before tackling larger parts of the infrastructure.

Standardization Across Power Distribution Control Cabinets

Getting things standardized really matters when it comes to making sure all those power distribution control cabinets from different manufacturers work together smoothly. When utilities stick to common tech specs and communication protocols across the board, they make it much easier to integrate systems from various companies. Different pieces of equipment then talk to each other without so many headaches. Standard practices cut down on wasted time during maintenance too. Setting these industry norms helps avoid problems that come from mixing incompatible systems. Think about how frustrating it gets trying to get parts from different brands to work together. Standardization basically creates a better connected grid overall. Power companies need this kind of consistency if they want their networks to run reliably while keeping costs under control.

Integration with Renewable Energy Systems

Bringing renewable energy into today's power grids isn't just important it's basically essential if we want sustainable and resilient energy infrastructure. The demand for clean power keeps rising, so our substation automation tech needs to catch up fast. These systems have to handle how unpredictable wind and solar power can be day to day. Smart grid technologies with better control features really matter here they keep everything running smoothly despite all those fluctuations. Power companies willing to invest in this kind of integration are paving the way for real change in our energy landscape. Their efforts create examples other businesses might actually follow when trying to switch over to more environmentally friendly operations down the road.

AI-Driven Predictive Maintenance Strategies

Predictive maintenance powered by artificial intelligence is changing how we maintain equipment and boost operational efficiency. By analyzing data patterns and using machine learning algorithms, utility companies can spot potential problems early on and schedule repairs before breakdowns happen. This approach saves money on emergency fixes and keeps services running smoothly for customers. For electric grid operators especially, being able to detect minor issues in transformers or generators before they cause major disruptions represents a game changer. The savings aren't just financial either – reliable service means fewer complaints from consumers and better reputation management for the company overall.

Evolution of Medium Voltage Control Cabinet Designs

Medium voltage control cabinets have been getting smarter over time, with better tech and user friendly interfaces becoming standard features now. The newer models really focus on making things safer for workers, easier to get into when needed, plus they come packed with advanced monitoring options that give operators real time data. These changes matter a lot because they help make automation work better inside substation environments. When companies upgrade their equipment with these improvements, it leads to electrical systems that run smoother and pose fewer risks to personnel. As energy management continues to change shape across different industries, having updated control solutions makes all the difference in day to day operations.

Table of Contents

-

Understanding Substation Automation in Modern Power Networks

- Defining Substation Automation Systems

- Key Components: From Electrical Distribution Panels to Smart Control Cabinets

- Core Technologies Driving Grid Transformation

- Intelligent Electronic Devices (IEDs) and Their Functions

- Communication Protocols in Medium Voltage Control Cabinets

- Data Acquisition in Power Distribution Control Cabinets

- Operational Benefits for Utility Providers

- Enhanced Reliability Through Low Voltage Control Systems

- Real-Time Monitoring in Electrical Distribution Panels

- Cybersecurity Considerations for Smart Control Cabinets

- Implementation Challenges and Solutions

- Retrofitting Legacy Systems with Modern Automation

- Standardization Across Power Distribution Control Cabinets

- Integration with Renewable Energy Systems

- AI-Driven Predictive Maintenance Strategies

- Evolution of Medium Voltage Control Cabinet Designs